Introduction

How To Splice Low Voltage Landscape Lighting Wire: Low voltage landscape lighting is a popular choice for homeowners looking to enhance the beauty and functionality of their outdoor spaces. Whether you want to highlight architectural features, illuminate pathways, or create a warm ambiance, this type of lighting offers numerous benefits. However, when it comes to installing or modifying low voltage landscape lighting, one important skill to have is the ability to splice the wire. Splicing allows you to connect multiple wires together or make repairs, ensuring a seamless and efficient lighting system.

Splicing low voltage landscape sensor lighting wire may seem like a daunting task for those who are unfamiliar with electrical work. However, with the right tools and techniques, it can be a straightforward process that anyone can learn. In this article, we will guide you through the steps of splicing low voltage landscape lighting wire, providing you with the knowledge and confidence to tackle this task.

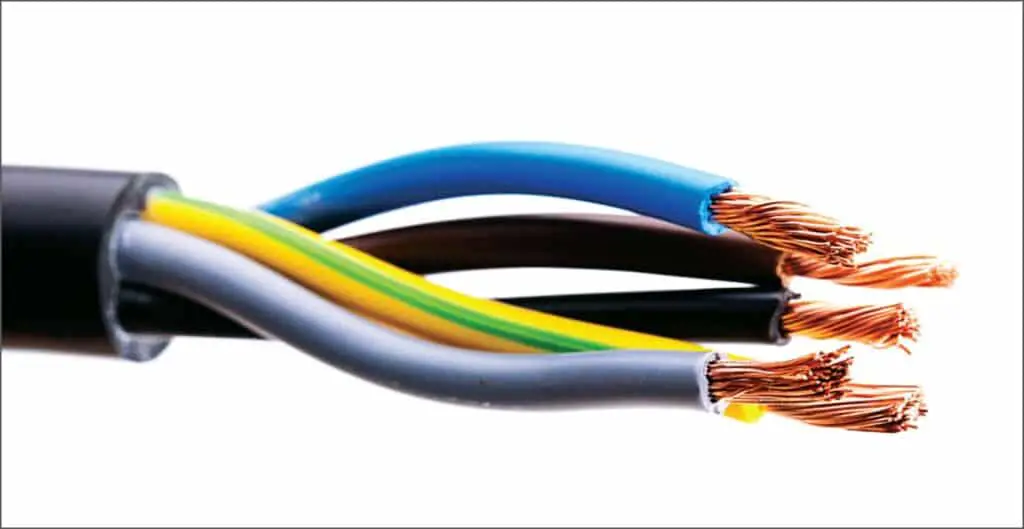

Understand the basics of low voltage landscape lighting before splicing wire. Low-voltage landscape lighting uses 12-volts, making it safer and easy to use. Lower voltage landscape lighting uses copper or aluminum wiring that can tolerate outdoor environments.

Low Voltage Landscape Lighting

When it comes to splicing low voltage landscape lighting wire, there are a few key tools and materials you will need. These include wire strippers, wire connectors, electrical tape, and a heat gun or torch. It is important to use the correct size wire connectors for your specific wire gauge to ensure a secure and reliable connection. Additionally, always make sure to follow safety precautions, such as turning off the power to the lighting system before working on the wires.

In the following parts, we will show you how to splice low voltage landscape lighting wire, including tips and methods. This article will give you the skills and confidence to splice low voltage landscape lighting wire to create a spectacular outdoor lighting display that enhances the aesthetic and functionality of your outdoor space.

Can you connect low voltage landscape lighting?

Low voltage landscape lighting is popular with people who wish to beautify and use their outdoor environments. This 12 volt lighting system is safer and easier to install than high voltage systems.If you are considering connecting low voltage landscape lighting, there are a few important factors to consider.

Firstly

It is crucial to plan your lighting design carefully. Determine the areas you want to illuminate and the specific lighting effects you want to achieve. This will help you determine the number and placement of light fixtures you will need. Consider highlighting architectural features, pathways, trees, and plants to create a visually appealing and functional outdoor space.

Secondly

You will need to gather the necessary materials and tools for the installation process. These may include low voltage light fixtures, a transformer, low voltage cable, connectors, and a timer or photocell for automated control. It is important to choose high-quality, weather-resistant fixtures and cables that are specifically designed for outdoor use to ensure durability and longevity.

Next

You will need to determine the power requirements for your lighting system. Calculate the total wattage of all the light fixtures you plan to install and choose a transformer with a suitable capacity. It is recommended to choose a transformer with a capacity that is 20% higher than the total wattage to allow for future expansion.

Once

You have gathered all the necessary materials and determined the power requirements, you can begin the installation process. Start by installing the transformer in a suitable location, preferably near an outdoor power source. Then, lay the low voltage cable along the desired lighting path, making sure to bury it at least 6 inches deep to protect it from damage. Connect the cable to the transformer and run it to each light fixture, making the necessary connections along the way.

Can you splice into landscape lighting?

Landscape lighting can greatly enhance the beauty and functionality of your outdoor space. Whether you want to highlight certain features, improve safety, or create a cozy ambiance, proper installation is crucial. One common question that arises when it comes to landscape lighting is whether it is possible to splice into existing lighting systems. In this article, we will explore the concept of splicing into landscape lighting and provide you with some insights.

Splicing into landscape lighting

Splicing into landscape lighting refers to the process of connecting additional fixtures or extending the existing wiring system. This can be done to add more lights to your outdoor area or to relocate existing fixtures. However, it is important to note that splicing into landscape lighting requires careful planning and adherence to safety guidelines.

Considerations for splicing

Before attempting to splice into your landscape lighting, there are a few important considerations to keep in mind. Firstly, it is crucial to understand the voltage and wattage requirements of your existing lighting system. This will help you determine whether it can handle the additional load of the spliced fixtures. Secondly, you need to ensure that you have the necessary tools and equipment for the job, such as wire connectors, electrical tape, and a wire stripper.

How do you find a short in low voltage landscape wiring?

When it comes to low voltage landscape wiring, finding a short can be a challenging task. A short circuit occurs when there is an unintended connection between two wires or between a wire and the ground, resulting in a disruption of the electrical flow. This can lead to various issues such as flickering lights, malfunctioning fixtures, or even complete failure of the system. To ensure the proper functioning of your low voltage landscape wiring, it is crucial to identify and fix any shorts that may be present.

Identifying the Short:

The first step in finding a short in low voltage landscape wiring is to visually inspect the entire system. Look for any exposed wires, damaged insulation, or signs of physical damage. Pay close attention to areas where the wires are exposed to the elements or where they may have been accidentally damaged during landscaping activities. If you notice any visible issues, such as frayed wires or loose connections, these could be potential sources of the short circuit.

Using a Multimeter:

If a visual inspection does not reveal any obvious problems, the next step is to use a multimeter to test the continuity of the wires. Start by disconnecting the power supply to the low voltage landscape wiring. Then, set your multimeter to the continuity or resistance mode and touch the probes to each end of the wire you suspect may have a short. If the multimeter beeps or shows a low resistance reading, it indicates the presence of a short circuit.

Isolating the Short:

Once you have identified a short circuit, the next step is to isolate the exact location of the short. This can be done by dividing the wiring system into sections and testing each section individually. Start by disconnecting all fixtures and accessories from the wiring system. Then, reconnect them one by one, testing for continuity after each connection. This process will help you pinpoint the specific section of the wiring where the short is occurring.

Repairing the Short:

Once you have located the short circuit, it is time to repair it. Depending on the nature of the short, the repair process may involve replacing damaged wires, fixing loose connections, or installing additional insulation. It is important to follow the manufacturer’s instructions and safety guidelines while making any repairs to ensure the longevity and safety of your low voltage landscape wiring system.

What is the common wire for low voltage lighting?

Low voltage lighting systems are becoming increasingly popular due to their energy efficiency and versatility. These systems operate on a lower voltage than traditional lighting, typically 12 or 24 volts, which offers several advantages. However, to ensure the proper functioning of low voltage lighting, a common wire is required.

What is a common wire?

A common wire, also known as a neutral wire or a return wire, is an essential component of low voltage lighting systems. It serves as a pathway for the electrical current to return to the power source after it has passed through the lighting fixtures. The common wire completes the electrical circuit and allows the system to function properly.

Importance of the common wire:

The common wire plays a crucial role in low voltage lighting systems. Without it, the electrical current would not have a path to return to the power source, resulting in an incomplete circuit and the lights not working. The common wire ensures that the electrical current flows smoothly and consistently, providing reliable illumination.

Connection of the common wire:

Low-voltage lighting systems connect the common wire to the power supply’s negative terminal or ground. Avoid electrical problems by properly connecting the common wire to the termination. For a secure connection, utilize high-quality connectors or wire nuts.

How many volts can low voltage wire handle?

Low-voltage wires can handle lower voltages than conventional wires. In low-voltage applications like lamp, doorbell, and thermostat wiring, it is used. Understanding the voltage capacity of low voltage wire is crucial to ensure the safety and efficiency of electrical installations.

What is low voltage wire?

Low voltage wire is typically made of copper or aluminum conductors that are insulated with a protective coating. The insulation material used in low voltage wire is specifically chosen to withstand the voltage levels it is designed for. This type of wire is usually smaller in diameter compared to standard electrical wires, making it more flexible and easier to handle during installation.

How many volts can low voltage wire handle?

The voltage capacity of low voltage wire can vary depending on the specific type and application. In general, low voltage wire is designed to handle voltage levels up to 50 volts or less. However, it is important to consult the manufacturer’s specifications and local electrical codes to determine the exact voltage rating for a particular type of low voltage wire.

Factors affecting voltage capacity:

Several factors can influence the voltage capacity of low voltage wire. The insulation material, wire gauge, and temperature rating are some of the key factors that determine the maximum voltage the wire can handle. Higher quality low voltage wires with thicker insulation and larger wire gauges can typically handle higher voltage levels. Additionally, the ambient temperature in which the wire is installed can also affect its voltage capacity, as extreme temperatures can degrade the insulation and reduce its ability to withstand voltage.

Splicing low voltage landscape lighting wire serves the purpose of connecting or extending wires in a landscape lighting system. It allows for the creation of a continuous electrical circuit, ensuring that power is properly distributed to all the lighting fixtures in the outdoor space. Splicing is necessary when installing new fixtures, adding additional lights, or repairing damaged wires.

Splicing is particularly important in low voltage landscape lighting systems because these systems operate at a lower voltage, typically 12 volts, for safety reasons. The low voltage reduces the risk of electrical shock and makes it easier to install and maintain the lighting system. However, due to the lower voltage, the wires used in these systems are often thinner and more delicate, requiring careful splicing techniques to ensure a secure and reliable connection.

What tools are needed to splice low voltage landscape lighting wire?

When it comes to splicing low voltage landscape lighting wire, there are a few essential tools that you will need to ensure a successful and secure connection. These tools include wire strippers, wire connectors, electrical tape, and a wire cutter.

Wire strippers are necessary to remove the insulation from the ends of the wires, allowing for a clean and proper connection. It is important to choose wire strippers that are specifically designed for the gauge of wire you are working with.

Wire connectors are used to join the wires together securely. There are various types of wire connectors available, such as twist-on connectors or crimp connectors. It is crucial to select connectors that are suitable for low voltage applications and provide a reliable and durable connection.

Electrical tape is used to insulate and protect the spliced wires. It helps to prevent any accidental contact or short circuits, ensuring the safety and longevity of the connection.

A wire cutter is necessary to trim the wires to the desired length and remove any excess. It is important to use a wire cutter that is appropriate for the gauge of wire you are working with to ensure clean and precise cuts.

How do you properly prepare the wire before splicing?

Before splicing low voltage landscape lighting wire, it is crucial to properly prepare the wire to ensure a secure and reliable connection. The preparation process involves a few important steps to guarantee the best results.

Firstly, it is essential to strip the insulation from the wire ends using a wire stripper or a utility knife. Carefully remove approximately 1/2 inch of the outer insulation to expose the inner conductors. Take caution not to damage the conductors during this process.

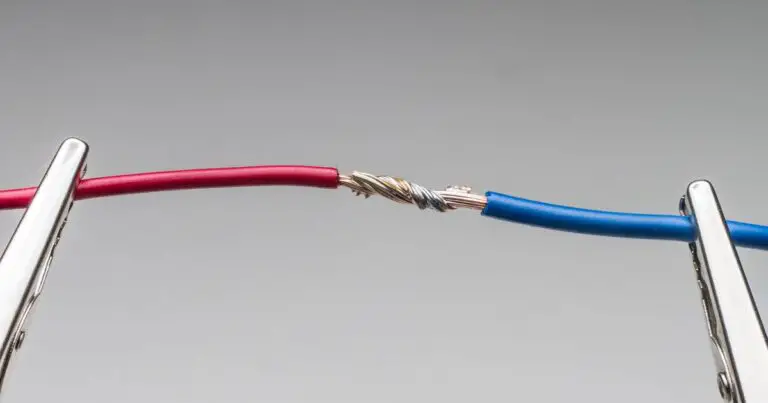

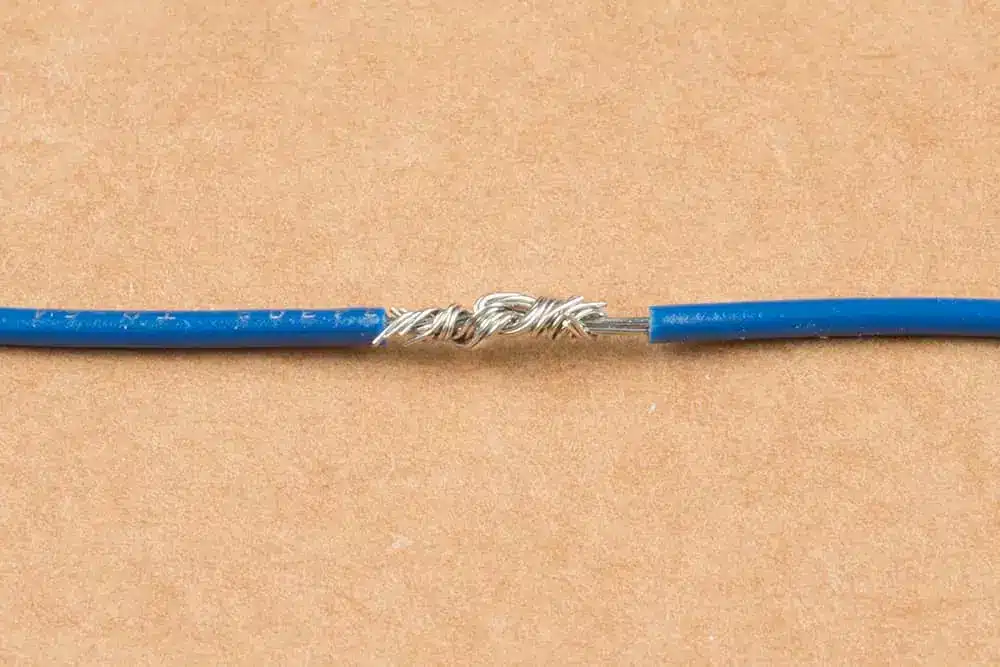

Secondly, after stripping the insulation, it is recommended to twist the exposed conductors together. This twisting action helps to create a solid connection and prevents any loose or frayed wires. Use pliers or your fingers to twist the conductors tightly together, ensuring a secure bond.

Lastly, once the conductors are twisted together, it is advisable to cover the connection with a waterproof wire connector or electrical tape. This additional layer of protection safeguards the connection from moisture, corrosion, and other environmental factors that could potentially compromise the integrity of the splice.

What are the steps involved in splicing low voltage landscape lighting wire?

When it comes to splicing low voltage landscape lighting wire, there are several important steps to follow. These steps ensure a secure and reliable connection, allowing the lights to function properly. Here is a breakdown of the process:

Step 1: Start by cutting the wire cleanly and evenly using wire cutters. It is crucial to have a straight cut to ensure a proper connection.

Step 2: Strip the insulation off the wire ends using wire strippers. Carefully remove about 1/2 inch of insulation to expose the bare wire. Be cautious not to damage the wire strands during this process.

Step 3: Twist the exposed wire strands together tightly. This creates a solid connection and prevents any loose or frayed wires.

Step 4: Slide a heat shrink tube over the twisted wire connection. Make sure the tube is long enough to cover the entire splice. Heat shrink tubes provide insulation and protection against moisture and corrosion.

Step 5: Use a heat gun to shrink the tube around the wire splice. Apply heat evenly to ensure a tight seal. The heat causes the tube to shrink and form a waterproof barrier.

Step 6: Finally, test the connection by turning on the low voltage landscape lighting system. Ensure that all lights are functioning properly and that there are no issues with the splice.

By following these steps, you can successfully splice low voltage landscape lighting wire and ensure a secure and long-lasting connection for your outdoor lighting system.

What are the steps involved in splicing low voltage landscape lighting wire?

When it comes to splicing low voltage landscape lighting wire, there are several important steps that need to be followed to ensure a proper and secure connection. Here is a step-by-step guide:

Step 1: Start by turning off the power to the lighting system. This is crucial to prevent any accidents or electrical shocks during the splicing process.

Step 2: Strip the insulation from the ends of the wires that need to be spliced. Use a wire stripper or a utility knife to carefully remove about 1/2 inch of insulation from each wire.

Step 3: Twist the exposed copper strands of the wires together. This will help create a solid connection and ensure good conductivity. Make sure the wires are tightly twisted to prevent any loose connections.

Step 4: Slide a heat shrink tube over the twisted wires. The heat shrink tube should be long enough to cover the entire exposed area of the twisted wires. Position the tube so that it covers the twisted section completely.

Step 5: Use a heat gun or a lighter to heat the shrink tube. As you apply heat, the tube will shrink and create a tight seal around the twisted wires. This will provide insulation and protect the connection from moisture and other elements.

Step 6: Finally, test the connection to ensure it is secure and functioning properly. Turn on the power to the lighting system and check if the lights are working as expected. If not, double-check the connection and make any necessary adjustments.

By following these steps, you can safely and effectively splice low voltage landscape lighting wire, ensuring a reliable and long-lasting connection for your outdoor lighting system.

Splicing Low Voltage Landscape Lighting

Splicing low voltage landscape lighting wire is a relatively simple process that can be accomplished with the right tools and techniques. By following the instructions provided, you can ensure that your landscape lighting system is properly connected and functioning efficiently. Splicing low voltage landscape lighting wire is a crucial skill for landscapers and DIYers alike, saving time and money.

One of the key benefits of splicing low voltage landscape lighting wire is the flexibility it provides. By splicing the wire, you can easily extend or modify your lighting system to accommodate changes in your landscape design. This allows you to create a customized lighting setup that enhances the beauty and functionality of your outdoor space. Additionally, splicing the wire allows for easier troubleshooting and maintenance, as individual sections can be isolated and repaired without affecting the entire system.

Conclusion

When splicing low voltage landscape outdoor lighting wire, it is important to use the proper tools and materials. This includes wire connectors, wire strippers, and electrical tape. Following the instructions carefully and ensuring that all connections are secure will help prevent any potential hazards, such as electrical shorts or voltage drops. It is also important to consider the location of the splice and protect it from moisture and other environmental factors that could damage the wire.

Splicing low voltage landscape lighting wire is a useful technique that offers flexibility, customization, and maintenance. Splice your wire and create a reliable and effective outdoor lighting system by following the instructions and utilizing the right equipment and supplies. Splicing low voltage landscape lighting wire is a practical and cost-effective way to improve your landscape’s aesthetics or safety.